Novec 1230 / FM 200 Refilling

Novec 1230 / FM 200 Refilling Specification

- Control Type

- Automatic/Manual

- Coverage Area

- Varies by installation and system design

- Coating Type

- Corrosion Resistant

- Connectivity Type

- Direct/Integrated with Fire Detection Panel

- Technology

- Clean Agent (Novec 1230/FM-200)

- Operating Pressure

- Standard Charging: 25 bar / 42 bar

- Installation Type

- Fixed System Recharging / Refilling

- Working Temperature

- -18C to +54C (agent range)

- Mounting Type

- Vertical/Horizontal/Wall Mounted

- Features

- Fast Acting, Eco-Friendly, Non-Conductive, Zero Ozone Depletion Potential, Minimal Downtime

- Shape

- Cylinder

- Fire Extinguisher Type

- Clean Agent / Gaseous Suppression

- Fire Class

- Class A, B, and C

- Application

- Fire Suppression System Refilling

- Max Flow Rate

- As per System Design

- Diameter

- Custom Cylinder Sizes

- Capacity

- Various Cylinder Capacities (10kg to 140kg+)

- Pressure

- 25 bar / 42 bar (as per agent)

- Service Response Time

- Within 24-48 hours (subject to location)

- Agent Type Options

- Novec 1230 (FK-5-1-12), FM-200 (HFC-227ea)

- Safety Standards

- CE Marked, PESO Approved Cylinder

- Leakage Testing

- Hydrostatic and Pneumatic Test Available

- Discharge Method

- Total Flooding, Local Application

- Refilling Certification

- ISO and OEM Certified Procedures

- Cylinder Material

- Seamless High Strength Steel

- Environmental Impact

- Zero Ozone Depletion, Low Global Warming Potential (Novec 1230)

- Service Type

- On-site Inspection, Refilling, and Re-commissioning

- Compliance Standard

- NFPA 2001, IS 15683

- Recycling Process

- Waste Agent Disposed as per Hazardous Standards

Novec 1230 / FM 200 Refilling Trade Information

- Certifications

- Ul Listed

About Novec 1230 / FM 200 Refilling

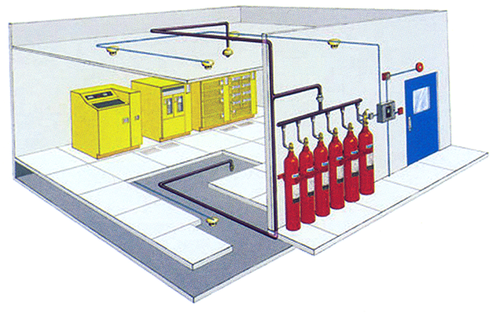

Foamtech Antifire Pvt. Ltd. is an upcoming company specializing in the designs, supply, installation & all about service of clean agent based automatic fire suppression systems. We are Authorized Distributors for automatic fire Suppression systems for the solutions from the global leader Fire Trace International LLC, USA. In Partnership with Fire Trace we have also established a complete UL listed/CCOE approved state of the art Filling Plant at our Kundali Facility.

Comprehensive Clean Agent Refilling Services

Our team provides a full suite of on-site clean agent refilling services for Novec 1230 and FM-200 systems. From initial inspection to safe disposal of waste agent and system re-commissioning, we ensure every step meets strict certification and compliance standards, maximising the integrity and performance of your fire suppression network.

Environmentally Responsible and Certified Process

We utilise OEM and ISO-certified refilling procedures, ensuring safe, eco-conscious handling of agents with zero ozone depletion and low global warming potential (particularly for Novec 1230). Our waste management and recycling processes are fully compliant with hazardous waste standards, underpinning our commitment to environmental stewardship.

Tailored Solutions for Diverse Applications

Our refilling solutions cater to a variety of installation types: from fixed, integrated systems to custom cylinder sizes and mounting preferences. Whether your system employs total flooding or local application, we provide seamless, high-strength steel cylinders suited for Class A, B, and C fire risks, supporting both automatic and manual controls.

FAQs of Novec 1230 / FM 200 Refilling:

Q: How is the refilling process for Novec 1230 and FM-200 carried out?

A: The process involves on-site inspection, hydrostatic or pneumatic leak testing, certified refilling of seamless high-strength steel cylinders under ISO/OEM standards, proper recycling or disposal of waste agents as hazardous material, followed by system re-commissioning to ensure operational safety and compliance.Q: What are the environmental benefits of using Novec 1230 and FM-200 agents?

A: Novec 1230 offers zero ozone depletion and low global warming potential, making it highly eco-friendly, while FM-200 is a clean agent with no ozone depletion. Both options ensure fire safety without compromising the environment.Q: When should I schedule refilling or servicing for my fire suppression system?

A: It is recommended to schedule servicing after any agent discharge, upon reaching the recharge date, or following regular maintenance intervals as specified in NFPA 2001/IS 15683. Immediate refilling is advised to maintain system readiness.Q: Where is your service available, and what is the typical response time?

A: Our services are available pan-India for distributors, exporters, importers, manufacturers, suppliers, and wholesalers. Typical response time is within 24-48 hours, depending on your location.Q: What types of fire suppression systems do you support?

A: We support clean agent gaseous suppression systems using Novec 1230 and FM-200, compatible with total flooding and local application methods. Solutions accommodate custom cylinder capacities, various mounting types, and integration with fire detection panels.Q: How are leakage and system integrity tested?

A: Rigorous hydrostatic and pneumatic tests are conducted on all cylinders and system piping after refilling, ensuring system safety and compliance with NFPA 2001, IS 15683, and related standards.Q: What are the key advantages of choosing your refilling services?

A: Our services offer minimal downtime, fast on-site response, adherence to international safety and environmental standards, certified refilling, and support for a wide range of cylinder sizes and system configurations, providing dependable and eco-conscious fire protection.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automatic Fire Suppression Systems Category

Fire Suppression System

Application : Fire suppression in industrial and commercial spaces

Mounting Type : Wallmounted or floormounted

Shape : Cylindrical

Features : Pressure gauge discharge nozzle durable construction

Fire Extinguisher Type : Clean agent fire suppression system

Fire Class : Class A B and C

Total Flooding Systems

Application : Fire suppression for large industrial spaces

Mounting Type : Ceiling or wallmounted nozzles

Shape : Nozzle shape varies conical spray

Features : Total flooding fast response nontoxic discharge

Fire Extinguisher Type : Gasbased (e.g. FM200 or inert gases)

Fire Class : Class A B and C

Fire Suppression Systems

Application : Industrial and server room fire protection

Mounting Type : Floormounted cylinders with piping connections

Shape : Cylindrical cylinders

Features : Multicylinder configuration automatic release mechanisms

Fire Extinguisher Type : Clean agent gas suppression system

Fire Class : ABC fire classes

Kitchen Fire Suppression Systems (K-Foam Technology)

Application : Kitchen Fire Suppression Systems

Mounting Type : Wallmounted for extinguisher; Ceiling for sprinklers

Shape : Rectangular extinguisher unit; standard cylindrical sprinklers

Features : Automatic detection and suppression of fire

Fire Extinguisher Type : Foambased suppression system

Fire Class : Class K (Cooking Oils and Fats)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS